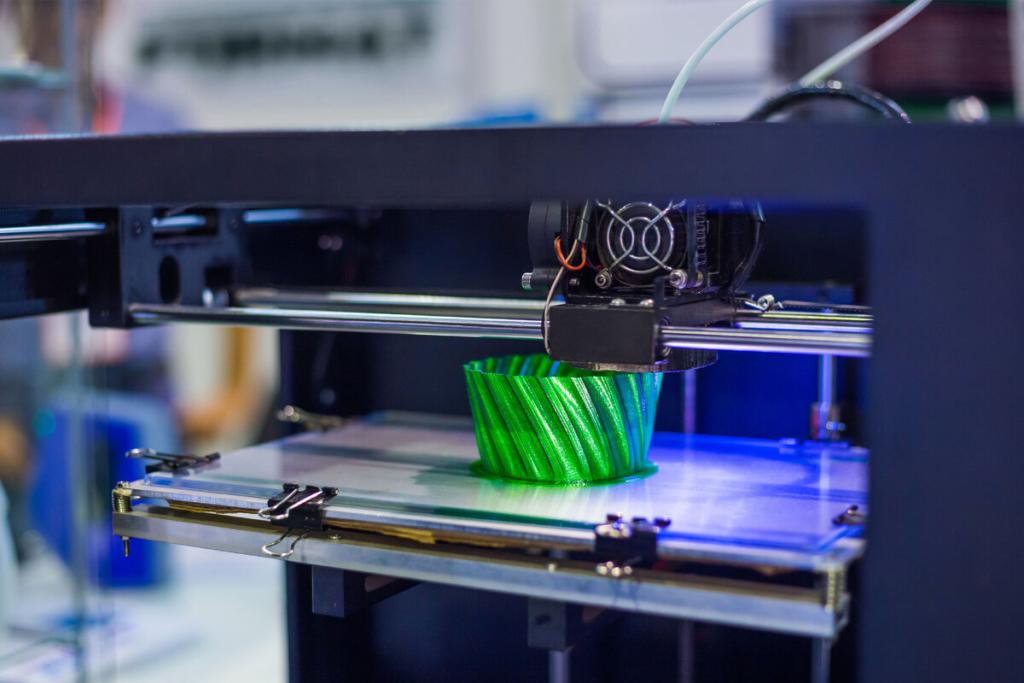

The rapid evolution of technology has significantly impacted various industries, and one of the most transformative advancements is 3D printing. This revolutionary technology is reshaping product development by enabling faster prototyping, reducing production costs, and fostering innovation. From manufacturing and healthcare to aerospace and consumer goods, 3D printing is proving to be a game-changer. But is it truly the future of product development? Let’s explore its impact, advantages, and challenges.

The Role of 3D Printing in Product Development

Traditionally, product development involved extensive design phases, physical prototyping, and time-consuming manufacturing processes. However, 3D printing—also known as additive manufacturing—allows designers and engineers to create prototypes and final products quickly, efficiently, and with greater precision. Key benefits include:

- Rapid Prototyping – Companies can create multiple iterations of a product within hours, significantly accelerating the development cycle.

- Cost Efficiency – Reducing the need for expensive molds and tooling lowers production costs, making manufacturing more affordable.

- Customization & Personalization – Unlike mass production, 3D printing allows for tailored products to meet specific customer needs.

- Material Versatility – From plastics and resins to metals and ceramics, 3D printing supports a wide range of materials for diverse applications.

- Sustainability – By minimizing material waste and supporting localized manufacturing, 3D printing promotes eco-friendly production methods.

- Complex Design Capabilities – 3D printing enables the creation of intricate designs that are difficult or impossible to achieve with traditional methods.

- Supply Chain Simplification – Reducing the need for multiple suppliers and complex logistics enhances efficiency and lowers overall production risks.

Industry Applications of 3D Printing

The widespread adoption of 3D printing is driving innovation across multiple industries:

- Manufacturing & Automotive: Automakers use 3D printing to create lightweight, durable car parts, reducing production costs and improving efficiency. This technology also allows for the rapid production of custom parts and prototypes.

- Healthcare & Medicine: 3D-printed prosthetics, implants, and even human tissues are transforming patient care and medical research. The ability to print biocompatible materials is pushing the boundaries of regenerative medicine and personalized healthcare.

- Aerospace & Defense: NASA and aerospace firms use 3D printing for spacecraft components, reducing weight and enhancing performance. The ability to print complex, high-performance parts on demand is revolutionizing space exploration and military applications.

- Consumer Goods & Fashion: Custom shoes, eyewear, and accessories are being produced through 3D printing, allowing for personalized fashion trends. Designers are experimenting with new materials and structures that were previously unattainable.

- Construction & Architecture: 3D-printed homes and buildings are emerging as a cost-effective and sustainable housing solution. This technology has the potential to address housing shortages and create resilient structures in disaster-prone areas.

- Education & Research: Schools and universities are incorporating 3D printing into their curricula to teach students about engineering, design, and material sciences, preparing the next generation for an advanced technological workforce.

Challenges & Limitations

While 3D printing is advancing rapidly, it still faces some hurdles:

- High Initial Costs: Industrial-grade 3D printers and materials can be expensive, posing a barrier to entry for smaller businesses.

- Limited Mass Production Capability: Traditional manufacturing is still more efficient for large-scale production, especially when high volumes are required.

- Material & Quality Constraints: Some 3D-printed materials lack the strength and durability of traditional materials, which may limit their use in high-stress environments.

- Intellectual Property Issues: The ease of replicating designs raises concerns about copyright and patent infringement, requiring new frameworks for digital rights management.

- Regulatory and Safety Concerns: Industries such as healthcare and aerospace must ensure that 3D-printed products meet strict safety and regulatory standards, which can slow adoption.

Future Outlook

As 3D printing technology continues to evolve, it is expected to become more accessible, cost-effective, and versatile. Advances in materials, speed, and automation will further solidify its role in product development. With continuous innovation, 3D printing is well on its way to transforming industries and shaping the future of manufacturing. The integration of artificial intelligence and machine learning into 3D printing processes will further enhance efficiency, optimizing designs and reducing errors.

Additionally, the rise of bioprinting—the ability to print human tissues and organs—could revolutionize medicine by reducing dependency on organ donors and enabling customized treatments. Similarly, the development of self-repairing materials in 3D printing could lead to products that can fix themselves over time, reducing waste and increasing longevity.

As global supply chains face increasing disruptions, on-demand manufacturing through 3D printing may become a strategic advantage for businesses looking to reduce dependency on overseas production and streamline logistics.

Conclusion

While 3D printing may not completely replace traditional manufacturing, it is undeniably revolutionizing product development. Companies that embrace this technology will benefit from increased efficiency, reduced costs, and greater flexibility in design. As the technology matures, 3D printing is set to become an integral part of the manufacturing landscape, making the future of product development more innovative than ever before. The possibilities are endless, and as 3D printing capabilities expand, we are likely to witness breakthroughs that redefine how products are designed, created, and consumed.