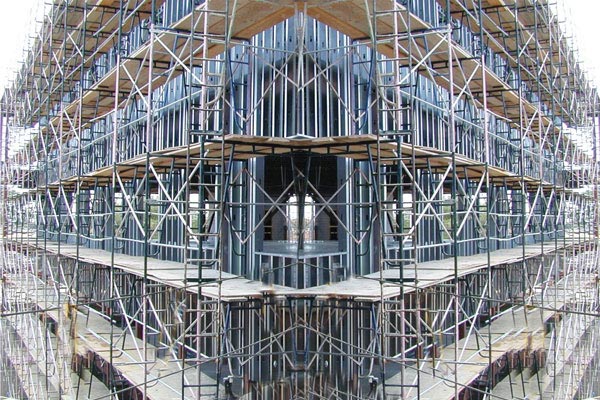

Construction projects need speed, safety, and structural reliability. Out of the multiple members that form the scaffolding system, the Scaffolding Verticals elements have a prominent role in supporting both the framework and the workers. Used to hold the framework plus workers, their positions are very strategic and well-built in terms of site efficiency and security, making them indispensable pieces of modern construction setups.

Strength and Stability for Heavy Load

Vertical elements in scaffolds are designed to absorb heavy weight, including the combined weight from workers, tools, and materials. This enables the user to use more than one level at the same time without safety being compromised. This design also keys into a robust vertical support system that carries its integrity without letting any significant dangerous shifts and collapses occur during some high-intensity tasks.

Integration with Quality Materials for Scaffolding

The performance of vertical supports is heavily dependent on the Scaffolding Materials used. Quality steel or alloy makes it possible that the system withstands heavy pressure and prevents the effects that would arise from being exposed to the weather and rough usage. Such long-wearing materials minimize maintenance requirements and prolong the equipment’s life, saving time and money in the long run while ensuring the safety of workers.

Enabling Quicker Assembly and Removal

Time efficiency is important in construction, and a well-planned scaffolding system can be erected and removed in a short period without compromising safety. Vertical supports are designed for simple connection with horizontal and diagonal members, making it easy for crews. This time benefit enables teams to make rapid platform adjustments as the job unfolds, keeping the project on track.

Precision Leveling with Specialty Accessories

To ensure any scaffold structure is safe, it should be perfectly horizontal on the ground, particularly in uneven ground conditions. For instance, height-adjustable supports like the Scaffolding U Jack from Winntus Formwork Pvt. Ltd. offer fine-tuning during leveling and support under heavy loads. Fine adjustments to the height and position of the scaffold ensure verticality of the supports and firmness and evenness on the working scaffold level. In this way, not only safety increases, but also comfort for the workers increases because they will then operate on a stable working surface.

Enhanced Worker Safety Above

At all construction sites, safety always takes top priority. Vertical supports are structured such that structurally strong under stress and form a secure system for guardrails, platforms, and ladders. Such supports hold the scaffold steadily in place, minimizing the risk of accidents attributable to wobbling or structural failure. The same, in turn, boosts reliability and confidence among workers to complete their activities instead of being distracted by safety concerns.

Supporting Multi-Level Operations

Major construction works require many teams to work at different heights at the same time. Vertical components ensure that each level remains strong and stable, even when the load is unevenly distributed. This is useful mostly in high-rise buildings, bridges, and industrial installations, where the workflow has to be uninterrupted among different sections for timely completion.

Durable Conditions in Challenging

Construction sites are often subjected to adverse environmental factors, such as rain, high temperature and wind. However, the corrosion-resistant vertical elements keep their strength and stability in each of these adverse conditions. This durability also minimizes downtime for repairs or replacements in the overall time savings of the project.

Speed Meets Safety-the Perfect Balance

Vertical support systems are the central elements of a site that is both quickly moving and safe. By improving load distributions and rapid setup and integrating them with today’s accessories and quality components, measurable increases in productivity and risk reduction are obtained. Moreover, quality verticals decrease insurance and liability costs during the project life. Countries that invest in safer sites use skilled labor, improve worker retention, and fasten client approval and cut rework. When project managers count the cost of ownership—downtime, repair, and safety accidents—the advantages of hardy vertical systems are even more obvious. In short, they are an investment in speed, safety, and overall project success. Prioritize them from day one.