In the world of modern science and technology, certain materials stand out because of their unique qualities and wide range of applications. One such material is Hafnium Oxide, also called Hafnia, with the chemical formula HfO₂. This compound has become highly important in electronics, optics, coatings, and even the nuclear industry.

In this article, we will explore everything you need to know about Hafnium Oxide—what it is, how it works, where it is used, and why it matters for the future.

What Is Hafnium Oxide?

Hafnium Oxide is an inorganic compound made from the rare metal hafnium combined with oxygen. It usually appears as a white, solid, and crystalline powder. Hafnium itself is closely related to zirconium and is found in minerals like zircon. When hafnium is purified and reacts with oxygen, it produces Hafnium Oxide.

The material is stable, heat-resistant, and chemically strong. These qualities make it a preferred choice for industries that require materials capable of handling extreme conditions.

Physical and Chemical Properties

The strength of Hafnium Oxide lies in its impressive set of physical and chemical properties. Here are some of the most important ones:

-

High Melting Point – Around 2,758°C (4,996°F), which means it can survive extremely high heat without breaking down.

-

Density – About 9.68 g/cm³, making it a very dense material.

-

Crystal Structure – At normal temperatures, HfO₂ has a monoclinic structure, but it can change to tetragonal or cubic at higher temperatures.

-

Dielectric Constant – Much higher than silicon dioxide, which makes it excellent for use in microchips and transistors.

-

Thermal Stability – It does not decompose easily even under high heat.

-

Chemical Resistance – Strong against most acids and alkalis, increasing its durability.

These features give Hafnium Oxide an edge over many other compounds used in industrial and electronic processes.

How Hafnium Oxide Is Produced

Hafnium Oxide is not found naturally but is created through different production methods. Some of the most common include:

-

Direct oxidation of hafnium metal – Hafnium is heated in the presence of oxygen to form HfO₂.

-

Decomposition of hafnium salts – Compounds like hafnium chloride or hafnium sulfate are processed to produce the oxide.

-

Thin film deposition methods – Advanced techniques like atomic layer deposition (ALD) and chemical vapor deposition (CVD) are used to create ultra-thin Hafnium Oxide coatings for electronic devices.

The production method depends on the intended use. For example, bulk powder can be made for coatings, while thin films are carefully engineered for microchips.

Applications of Hafnium Oxide

Hafnium Oxide has a wide range of applications thanks to its unique properties. Below are the major industries where it plays an important role:

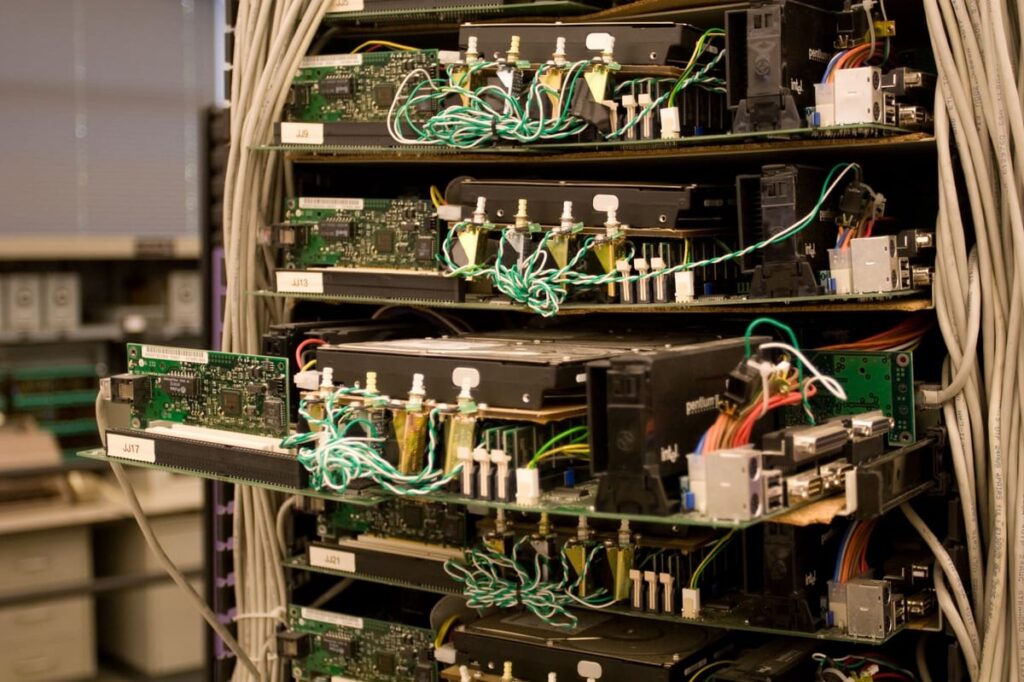

1. Electronics

The electronics industry is the biggest user of HfO₂. It is applied as a high-k dielectric material in microchips, replacing silicon dioxide. This allows manufacturers to create smaller and more efficient transistors for computers, smartphones, and other devices.

Applications in electronics include:

-

Gate dielectrics in field-effect transistors (FETs)

-

Capacitors with high storage capacity

-

Memory devices like DRAM and flash memory

2. Optics

Because Hafnium Oxide is transparent to both visible and infrared light, it is used in optical coatings. It improves the performance of:

-

Camera lenses

-

Laser systems

-

Telescope mirrors

-

Optical filters

3. Protective Coatings

HfO₂ is applied as a thermal and chemical barrier on metals and ceramics. These coatings help protect turbines, jet engines, and reactors from damage caused by extreme heat and corrosion.

4. Nuclear Industry

Hafnium is well known for its ability to absorb neutrons. Hafnium Oxide also benefits from this property and is used in:

-

Nuclear reactor control rods

-

Radiation shielding materials

5. Ceramics

Hafnium Oxide is used in making high-performance ceramics that can resist very high temperatures. Such ceramics are useful in aerospace, defense, and energy industries.

6. Catalysis

In the chemical industry, Hafnium Oxide sometimes works as a catalyst or catalyst support. Its surface properties make it useful for speeding up reactions in processes like hydrocarbon conversion.

Benefits of Using Hafnium Oxide

The advantages of HfO₂ explain why it has become so popular in advanced industries:

-

Energy Efficiency in Electronics – Helps reduce power consumption in modern chips.

-

Durability – Withstands high temperatures and harsh environments.

-

Versatility – Works in electronics, optics, nuclear systems, and coatings.

-

Transparency – Useful in optical devices without blocking light.

-

Safety in Nuclear Use – Plays a role in controlling nuclear reactions.

These benefits make it one of the most valuable oxides in modern applications.

Limitations and Challenges

Despite its many advantages, Hafnium Oxide faces certain limitations:

-

High Cost – Hafnium is a rare element, and extracting it is expensive.

-

Limited Supply – Hafnium is less abundant compared to other metals.

-

Complex Processing – Advanced equipment is needed for thin film deposition.

-

Competition from Other Materials – In some areas, alternatives like zirconium oxide may be used instead.

These challenges mean that while HfO₂ is important, its use is often limited to high-value industries.

The Future of Hafnium Oxide

The demand for Hafnium Oxide is expected to rise in the coming years. With the growing need for smaller and more powerful electronics, materials like HfO₂ will remain at the heart of innovation.

Future uses may include:

-

Next-generation nanoelectronics for faster and more efficient computing.

-

Photonics and light-based technologies.

-

Energy storage devices, including advanced batteries and supercapacitors.

-

Space technology, where heat resistance is critical.

As research continues, Hafnium Oxide may unlock even more exciting possibilities.

Why Hafnium Oxide Matters

Hafnium Oxide may not be a household name, but it silently powers much of the technology around us. Without it, modern transistors and chips would not be as efficient. Optical devices would be less reliable, and nuclear systems would be harder to manage safely.

It stands as a great example of how a single material can influence multiple industries and drive innovation in ways most people do not realize.

To read more blog: Forecasting the India Textile Specialty Chemicals Market Size from 2025 to 2030

Conclusion

Hafnium Oxide (HfO₂) is a powerful material that combines heat resistance, chemical stability, and excellent electrical properties. It has already transformed industries like electronics, optics, ceramics, and nuclear energy.

While its cost and supply challenges exist, the benefits far outweigh the drawbacks. As we move toward an era of faster computing, cleaner energy, and advanced technology, Hafnium Oxide will remain at the center of scientific and industrial progress.

It is safe to say that Hafnium Oxide is not just another chemical compound—it is a building block of the future.

FAQs on Hafnium Oxide

1. What is Hafnium Oxide used for?

It is used in electronics, optical coatings, protective layers, nuclear reactors, and high-performance ceramics.

2. Why is Hafnium Oxide better than Silicon Dioxide in chips?

Because it has a higher dielectric constant, allowing transistors to be smaller and more energy-efficient.

3. Is Hafnium Oxide safe to handle?

Yes, it is stable and non-toxic under normal conditions, but fine powders should be handled carefully to avoid inhalation.

4. How is Hafnium Oxide produced?

It is usually made by oxidizing hafnium metal or decomposing hafnium salts. Thin films are made using advanced deposition methods.

5. Will Hafnium Oxide become more important in the future?

Yes, with the rise of nanoelectronics, renewable energy, and space technology, its importance will only grow.