The rainfall type stucco applicator is a specialized machine designed to revolutionize the ceramic shell forming process by providing a uniform coating of refractory particles on patterns or “clusters”. This technology is essential for industries such as investment casting, where the quality and consistency of ceramic shells directly impact casting precision and final product integrity. The following article explores the design, functionality, benefits, and applications of rainfall type stucco applicators.

Read More: https://www.ic-machines.com/rainfall-type-stucco-applicator/

Introduction to Rainfall Type Stucco Applicators

The rainfall type stucco applicator is engineered for the precise application of sand or stucco materials onto wet slurry-coated wax clusters during the ceramic shell construction phase. Unlike conventional methods that may result in irregular coatings or material waste, this machine produces a controlled “rain” of sand, ensuring even distribution over the entire surface of the cluster. The process can be performed manually or integrated with robotic systems for enhanced automation and consistency.

How the Rainfall Stucco Applicator Works

The core mechanism of the rainfall type stucco applicator involves generating a curtain or rain of sand that falls uniformly onto the slurry-dipped cluster suspended beneath it. The cluster, usually composed of wax patterns bound together, is coated with a refractory slurry, after which it is positioned under the sand rain.

Key Steps:

-

Slurry Dip: The wax cluster is dipped into a ceramic slurry, ensuring all surfaces are wet and ready to receive the refractory material.

-

Sand Rainfall: The cluster is held under the applicator or moved through the rain curtain. Refractory sand, such as zircon or silica, rains down evenly, adhering to the sticky slurry coat exposed on the cluster.

-

Uniform Coating: Operators or automated systems rotate and manipulate the cluster to expose all surfaces, ensuring complete and uniform coverage with minimal sand usage and spillage.

Features and Design Innovations

Modern rainfall type stucco applicators, such as the RTS1000 model, include several advanced design features:

-

Uniform Rain Curtain: Ensures a full and consistent coverage with minimal waste or uneven coating.

-

Minimum Sand Consumption: Optimized design reduces the amount of expensive refractory sand required.

-

Vibration-Free Operation: The machine is engineered to minimize vibrations, which can otherwise disturb the cluster and reduce coating quality.

-

Low Spillage: Design reduces the risk of valuable material falling outside the intended area, lowering operational costs.

-

Automation Compatibility: Easily integrates with automation systems, facilitating robotic operation for high-volume manufacturing environments.

-

Maintenance-Free Performance: The applicator requires minimal upkeep, offering reliable long-term performance.

-

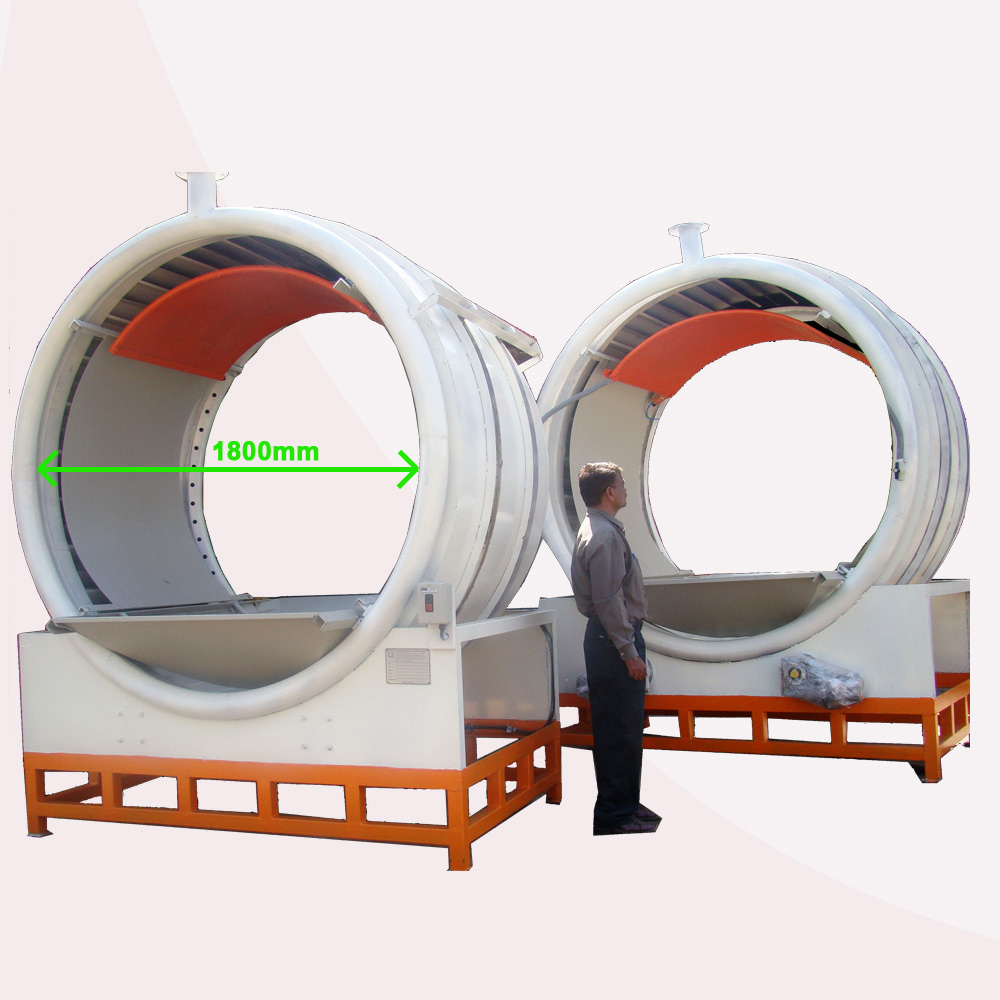

Size Options: Standard diameters of 1000mm and 1800mm accommodate diverse production needs.

Advantages Over Traditional Stuccoing Techniques

Traditional stucco application methods, such as manual hand sprinkling or tumbling, often result in variable coating thickness, increased material waste, and inconsistent shell quality. Rainfall type stucco applicators address these limitations through:

-

Consistent Coating: The rain curtain creates a repeatable, reliable process for even material distribution.

-

Material Savings: Controlled sand flow and minimal spillage mean less waste and lower costs for expensive refractory particles.

-

Reduced Labor: Automation lowers manual handling, improving safety and reducing labor costs.

-

Improved Shell Quality: Uniform particle distribution enhances shell integrity, reducing casting defects.

Applications in Industry

Rainfall type stucco applicators are widely used in the investment casting sector, particularly in foundries producing high-precision metal components for industries such as aerospace, automotive, energy, and more. The technology supports production processes that require:

-

High Repeatability: Critical for mass-produced components meeting strict dimensional tolerances.

-

Complex Geometries: Uniform sand coating allows for intricate mold shapes without thin spots or excessive coating.

-

Automation Integration: Facilitates the use of robots for moving clusters under the applicator, enabling seamless, high-volume automated shell building.

Selecting the Right Rainfall Type Stucco Applicator

Choosing a rainfall stucco applicator involves considering several factors:

-

Production Scale: Larger applicators (1800mm diameter) suit higher volume operations, while smaller machines (1000mm diameter) fit compact setups.

-

Material Type: The type and grain size of sand or refractory material must match the shell requirements for the intended casting method.

-

Degree of Automation: Facilities with existing robotics and automation infrastructure can select machines designed for automated integration.

Maintenance and Operational Efficiency

One of the standout features of modern rainfall type machines is their near maintenance-free operation. Quality applicators are built with durable materials and robust mechanical systems that withstand constant use in demanding foundry environments. Operators benefit from reduced downtime and simplified maintenance schedules, helping foundries maximize throughput and minimize costs.

Future Trends: Robotic Stucco Application

As investment casting technology advances, the integration of robotic stucco application is rapidly growing in popularity. Robots efficiently move the cluster under the applicator at precisely controlled speeds and angles, guaranteeing maximum coverage and repeatability. This trend is expected to further reduce labor, standardize shell quality, and improve process data collection for quality assurance.

Conclusion

The rainfall type stucco applicator is an innovative solution for ceramic shell manufacturing in the investment casting industry, delivering consistency, efficiency, and quality in every application. With benefits like minimal material waste, ease of automation, and robust maintenance-free operation, it has become indispensable for modern foundries seeking to optimize their shell-building process. As automation technology continues to evolve, rainfall stucco applicators will remain at the forefront of precision casting methodology.

Address –

H16, Maharashtra Industrial Development Corporation, Gokul – Shirgaon, Dist – Kolhapur, 416234 Maharashtra State, INDIA.

Our Contact :

+91 9422417760

vinaysangle@gmail.com

Visit Official Site: https://www.ic-machines.com/