In today’s fast-paced industrial world, businesses cannot afford downtime, contamination, or inefficiency in their processes. Whether it’s oil and gas, petrochemicals, aviation fuel, or compressed air systems, one component plays a vital role in ensuring smooth operations—the coalescer.

If your business depends on clean fuels, lubricants, or compressed gases, investing in a high-quality coalescer is not just a choice—it’s a necessity. In this blog, we’ll explore what a coalescer is, how it works, its commercial benefits, and why it’s the ultimate solution for industrial filtration.

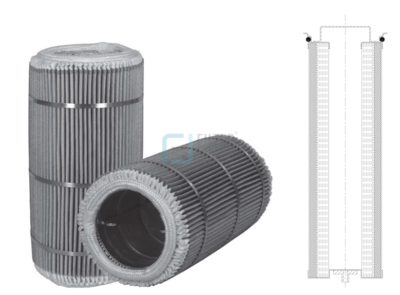

What is a Coalescer?

A coalescer is a specialized filtration device designed to separate liquid droplets or fine mist from gas or liquid streams. Unlike traditional filters, which simply trap particles, a coalescer works by gathering (coalescing) small droplets into larger ones, making it easier to separate them from the fluid stream.

This makes coalescers highly effective in removing:

-

Water from fuel systems

-

Oil mist from compressed air

-

Hydrocarbon liquids from gas streams

-

Contaminants from petrochemical processes

By ensuring purity and efficiency, coalescers help protect machinery, reduce downtime, and extend the life of industrial systems.

How Does a Coalescer Work?

The working principle of a coalescer is both simple and powerful.

-

Capture Phase – Tiny droplets of water, oil, or contaminants are captured by the coalescer’s filter media.

-

Coalescence Phase – These tiny droplets merge into larger droplets as they pass through.

-

Separation Phase – The larger droplets separate naturally due to gravity or centrifugal force, leaving behind a cleaner fluid stream.

This process ensures that even microscopic contaminants are effectively removed, delivering superior performance compared to conventional filters.

Types of Coalescers

Depending on industry requirements, coalescers come in various designs. Some of the most common types include:

-

Gas-Liquid Coalescer – Removes liquid aerosols and droplets from natural gas or compressed gas streams.

-

Liquid-Liquid Coalescer – Separates immiscible liquids, like water from fuel or oil.

-

Air-Oil Coalescer – Commonly used in compressed air systems to remove oil mist and ensure dry, clean air supply.

-

Fuel Coalescer – Protects engines, turbines, and aviation fuel systems by removing water and fine particles.

Why Businesses Need a Coalescer

If you’re running industrial equipment, the stakes are high. Contaminated fluids can lead to:

-

Equipment wear and tear

-

Reduced efficiency

-

Increased downtime

-

Costly repairs and replacements

By installing a coalescer, businesses can:

-

Protect Equipment: Prevent corrosion, damage, and malfunction.

-

Increase Efficiency: Clean fluids improve overall system performance.

-

Reduce Maintenance Costs: Extend the life of filters, machinery, and pipelines.

-

Improve Product Quality: Deliver purer fuel, chemicals, or air supply.

-

Ensure Compliance: Meet strict industry regulations for fluid purity.

Applications of Coalescers Across Industries

The versatility of a coalescer makes it indispensable across multiple sectors:

-

Oil & Gas Industry – Removes water and contaminants from natural gas and crude oil.

-

Aviation – Ensures fuel quality for jet engines by removing water and fine particles.

-

Power Generation – Protects turbines by keeping fuel and lubrication clean.

-

Manufacturing – Provides clean compressed air and lubricants for machinery.

-

Chemical & Petrochemical Plants – Ensures purity in production processes.

Choosing the Right Coalescer for Your Business

Not all coalescers are created equal. When selecting one, consider:

-

Flow Rate Requirements – Match coalescer size to your system capacity.

-

Type of Contaminants – Choose gas-liquid, liquid-liquid, or air-oil coalescers based on application.

-

Efficiency Rating – Higher efficiency means cleaner output and better protection.

-

Maintenance Needs – Look for long-life, easy-to-maintain coalescers.

Partnering with a trusted supplier ensures you get the right solution tailored to your business needs.

Why Invest in a Coalescer Now?

In industries where downtime equals lost revenue, investing in a coalescer is one of the smartest business decisions. It’s not just about cleaner fuel, oil, or air—it’s about protecting your profits, equipment, and reputation.

Every unfiltered drop of water, oil mist, or contaminant has the potential to damage your system. A high-quality coalescer provides peace of mind, efficiency, and long-term savings.

Final Thoughts

A coalescer is more than a filter—it’s a performance booster and a cost saver for industries that demand reliability. From oil and gas to aviation and power generation, the right coalescer ensures clean operations, protects equipment, and enhances efficiency.

If you’re serious about reducing downtime and maximizing ROI, it’s time to upgrade your filtration system with a trusted coalescer solution.

Read Blogs – https://regic.net/advantages-and-disadvantages-of-custom-software-development/