Understanding Why Exterior Trim Fails

Most exterior trim is made from plastic, rubber, or a combination of both. Over time, these materials break down due to:

-

UV exposure

-

Heat cycling

-

Road chemicals and pollution

-

Improper cleaning products

That gray or white haze you see isn’t just dirt—it’s oxidation and material degradation. Covering it up without addressing the cause usually leads to short-lived results.

A Common Mistake I See All the Time

One personal observation: many people jump straight to a trim dressing without cleaning the surface first. The trim looks good for a few days, then fades unevenly or attracts dust. The issue isn’t the product—it’s the skipped prep work.

Step One: Deep Cleaning Before Restoration

Restoration starts with a truly clean surface. If contaminants remain, no restoration product will bond or last properly.

Use the Right Cleaner

A dedicated trim cleaner or diluted all-purpose cleaner works well. Avoid harsh degreasers unless absolutely necessary, especially on older trim.

Use a soft-bristled brush to work the cleaner into textured plastics. This pulls oxidation and embedded grime out of the pores rather than pushing it around.

Rinse gently or wipe away residue with a damp microfiber towel. High-pressure water can force moisture behind trim pieces, which causes issues later.

Don’t Skip Drying Time

Trim needs to be completely dry before any restoration or protection step. Moisture trapped in porous plastic dilutes products and leads to streaking.

Insider tip: if the weather is humid, use compressed air or a gentle blower to dry seams and textured areas thoroughly.

Choosing the Right Restoration Method

Not all trim needs the same treatment. Matching the method to the condition of the trim is key.

Mild Fading: Restoration Creams or Dressings

For trim that’s faded but still structurally sound, quality restoration creams or trim-specific protectants work well. These products replenish oils and darken the surface without leaving it greasy.

Apply sparingly and evenly. Multiple light coats outperform one heavy application every time.

Heavy Oxidation: Restoration Compounds or Prep Products

Severely faded trim often needs a more aggressive approach. Some trim restoration systems include a prep step that removes oxidized layers before applying protection.

Work slowly and test a small area first. Aggressive products can permanently alter the texture if overused.

Heat Methods: Use With Caution

Heat guns are sometimes used to revive faded plastic by bringing oils back to the surface. While this can work, it’s risky.

I’ve seen trim permanently warped or unevenly darkened due to excessive heat. If you use this method, keep the heat moving and stay well below the melting point.

In most cases, chemical restoration is safer and more predictable.

Protecting Trim for Long-Term Results

Restoration without protection is temporary. Once trim is revived, it needs shielding from UV and environmental exposure.

Why Protection Matters More Than Shine

Many off-the-shelf trim dressings look good initially but offer minimal UV resistance. They fade quickly and often leave residue that attracts dust.

Longer-lasting solutions include trim coatings or sealants designed specifically for exterior plastics. These products bond to the surface rather than sitting on top of it.

As explained in this guide on ceramic coating mansfield, protective coatings—when applied correctly—help reduce UV damage and make ongoing maintenance easier. While often discussed in terms of paint, the same principles apply to exterior trim protection.

Restoring Rubber Seals and Weatherstripping

Plastic trim gets most of the attention, but rubber seals deserve just as much care.

Clean Gently, Restore Slowly

Rubber dries out and cracks when exposed to harsh cleaners. Use mild soap or a rubber-safe cleaner and a soft cloth.

After cleaning, apply a rubber conditioner designed to restore flexibility, not gloss. The goal is to keep seals supple, not shiny.

Insider tip: lightly condition door and trunk seals before winter. It reduces sticking and helps prevent tearing in cold weather.

Metal Trim: A Different Approach

Some vehicles—especially older models—feature metal trim around windows or along body lines.

These areas require:

-

Gentle metal polish for oxidation

-

Careful masking to protect surrounding paint

-

Light pressure to avoid thinning the metal finish

Metal trim should never be treated with plastic restoration products. It sounds obvious, but it’s a surprisingly common mistake.

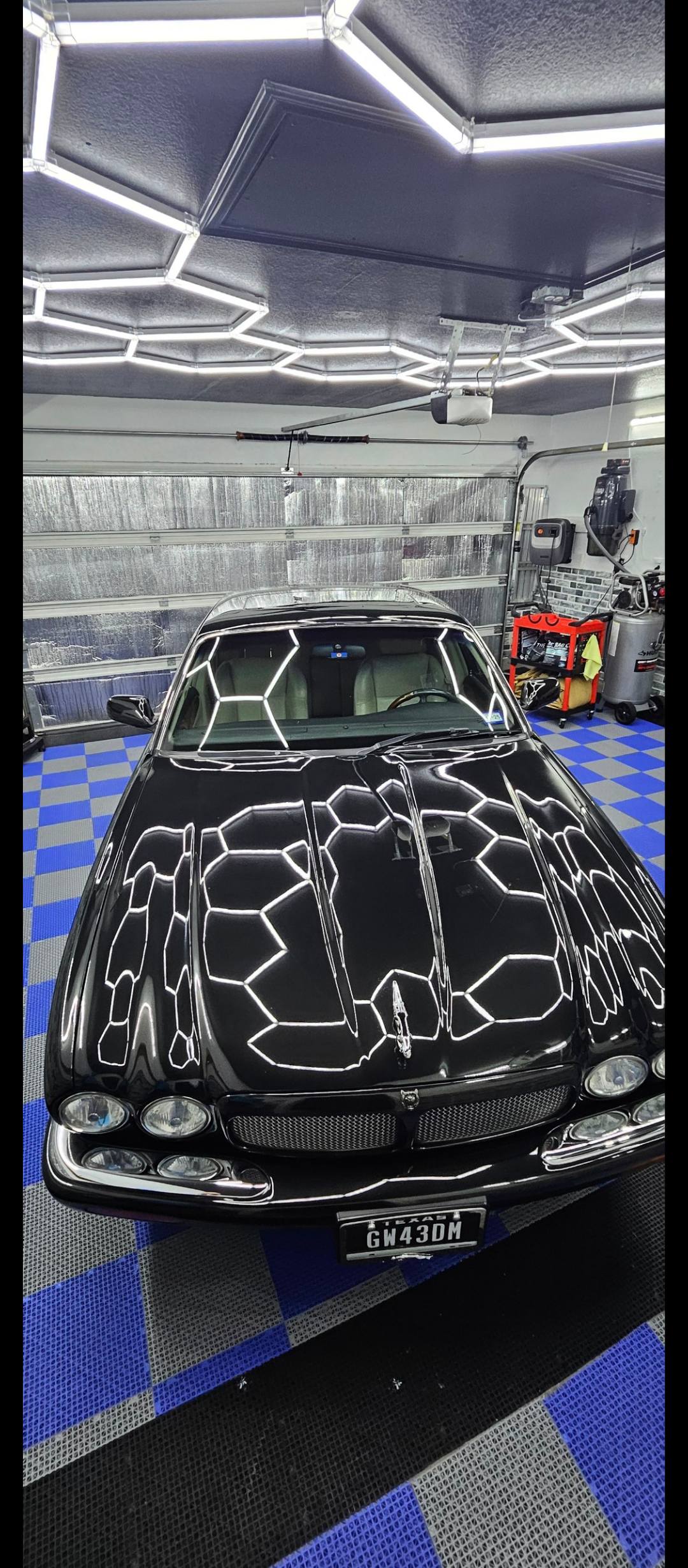

Blending Trim With the Overall Look

A successful trim restoration shouldn’t draw attention to itself. Over-darkened or overly glossy trim can look out of place, especially on older vehicles.

Aim for Consistency

Step back and view the car as a whole. Trim should complement the paint, not overpower it.

On classic or older cars, a more natural satin finish often looks more authentic than deep black gloss.

Maintenance: Keeping Trim Looking Good

Once restored and protected, trim is easy to maintain—if you stay consistent.

Simple habits help:

-

Wash trim with pH-neutral car shampoo

-

Avoid harsh chemicals and degreasers

-

Reapply protectant as needed, not automatically

I’ve seen trim restorations last over a year simply because the owner avoided aggressive cleaners afterward.

When Replacement Makes More Sense

Not all trim can be saved. Severely cracked, brittle, or warped trim may look better temporarily after restoration, but it won’t last.

In those cases, replacement is often the better long-term solution. Restoration should enhance good material, not disguise failure.

Final Thoughts: Thoughtful Restoration Beats Quick Fixes

Exterior trim restoration is one of the most satisfying detailing tasks when done correctly. It restores contrast, sharpens body lines, and elevates the overall appearance of a vehicle.

The key is patience. Clean thoroughly, choose the right method, protect the surface, and resist the urge to overdo it. When trim looks factory-correct rather than freshly coated, you’ve done it right.

Also read for more information so click here.