Metal fabrication has changed dramatically over the years, moving from basic manual processes to highly advanced and precise manufacturing methods. Today, almost every industry depends on fabricated metal components that offer durability, accuracy, and long-term performance. As technology continues to evolve, metal fabrication has become more efficient, faster, and capable of producing complex designs that were once impossible.

This blog explores how modern metal fabrication improves overall product quality and boosts efficiency in the manufacturing world.

Advanced Tools for Higher Precision

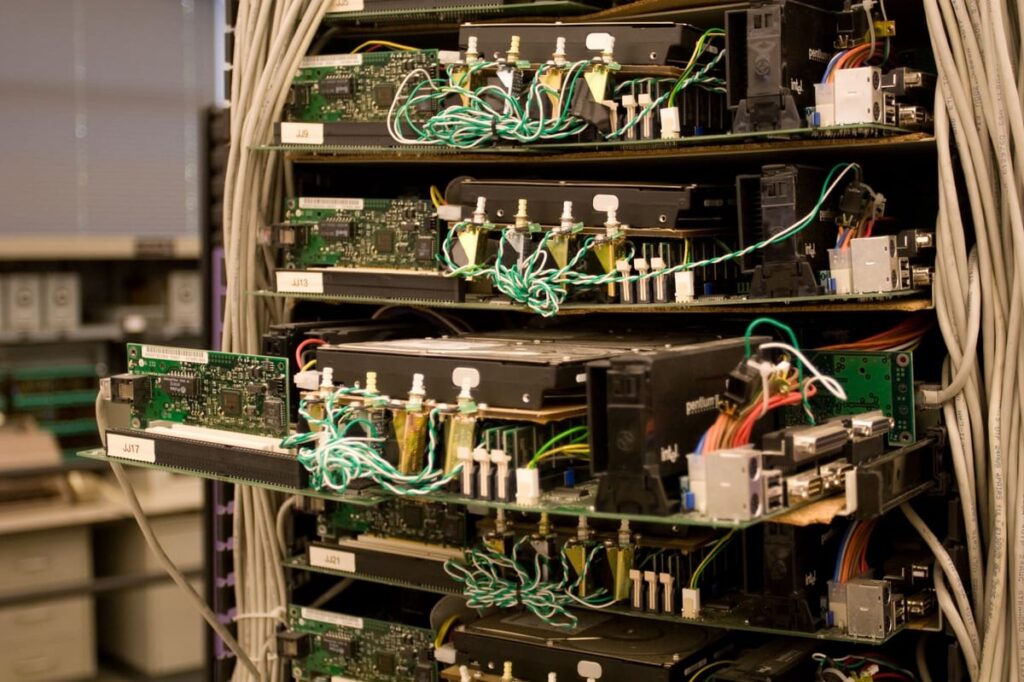

One of the main reasons metal fabrication has evolved so much is the introduction of advanced tools and machines. Laser cutters, CNC machines, plasma cutters, and automated welding systems allow manufacturers to achieve extremely accurate results. These machines can cut and shape metal with minimal errors, ensuring that every piece fits perfectly during assembly.

Precision is important for industries like automotive, aerospace, and medical equipment manufacturing, where even a small defect can cause major problems. With better tools, companies now produce cleaner cuts, smoother edges, and stronger welded joints.

Also read 5G Expansion: Connecting the World at Lightspeed

Faster Production with Automation

Automation has become a major part of modern metal fabrication. Instead of relying only on manual labour, factories now use robotic systems to handle repetitive and complex tasks. Automated welding robots, assembly machines, and cutting systems help increase production speed without compromising quality.

Automation also reduces errors caused by fatigue or human limitations. This means less waste, fewer rejected parts, and a more consistent final product. For high-volume industries, automation ensures that orders are completed on time and at a lower cost.

Improved Material Options

Metal fabrication is no longer limited to basic steel or aluminium. Today, manufacturers work with a wide range of materials, including stainless steel, titanium, copper alloys, brass, and high-strength composites. Each material offers unique benefits for different industries — for example, titanium is lightweight yet incredibly strong, making it ideal for aerospace components.

These improved material options allow designers and engineers to select the perfect metal for their exact requirements, resulting in stronger, longer-lasting, and more efficient products.

Better Product Customisation

Modern metal fabrication techniques make it much easier to create custom shapes and unique products. Industries often need parts that match specific designs, sizes, or performance requirements. With advanced fabrication methods like CNC machining, waterjet cutting, and precision welding, companies can easily produce custom components without delays.

This is especially useful in sectors such as industrial machinery, construction, renewable energy, and medical equipment, where custom-built parts are common. Custom fabrication also helps companies improve product performance by designing components that match their exact needs.

Stronger and More Reliable Assemblies

The quality of joints, welds, and fitted components has improved significantly in modern fabrication. Advanced welding techniques such as MIG, TIG, and robotic welding ensure deeper penetration, stronger bonds, and cleaner finishes. This results in assemblies that can handle heavy loads, high temperatures, and long-term wear.

For industries that require durability — such as oil and gas, construction, and transportation — reliable metal assemblies are essential. Improved welding and joining techniques help extend the lifespan of equipment, reducing maintenance costs.

Energy-Efficient and Eco-Friendly Processes

As sustainability becomes more important, modern metal fabrication focuses on reducing waste and energy use. New machines consume less power, while better cutting methods reduce scrap material. Many manufacturers also recycle leftover metal, turning waste into reusable material.

Energy-efficient fabrication not only lowers production costs but also supports eco-friendly manufacturing practices. This makes metal fabrication more sustainable and responsible for the environment.

Smarter Design Through Digital Technology

Computer-aided design (CAD) software has completely transformed the planning and design stage. Engineers can now create 3D models, test part performance, and simulate real working conditions before production begins. This helps identify potential issues early and ensures accurate results during fabrication.

Digital designs also allow for better communication between manufacturers, designers, and clients. Everyone involved can review the design, request changes, and ensure the final product meets all requirements.

Final Thoughts

Modern metal fabrication is a blend of advanced technology, smarter tools, and improved materials. These advancements help manufacturers produce stronger, cleaner, and more precise metal components while reducing costs and speeding up production. As industries continue to demand high-quality, customised solutions, metal fabrication will remain an essential part of modern manufacturing.