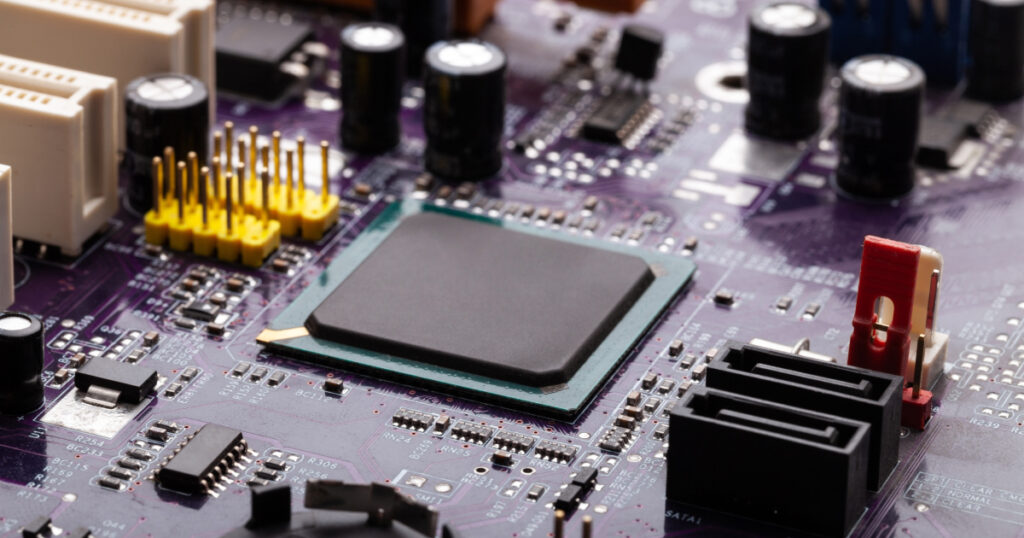

In today’s fast-paced electronics industry, High-Density Interconnect (HDI) printed circuit boards (PCBs) play a crucial role in enabling compact, high-performance devices. From smartphones and wearables to aerospace and medical equipment, HDI PCBs are the backbone of modern innovation.

But while the demand for HDI PCBs is soaring, not every manufacturer is created equal. Choosing the right HDI PCB manufacturer can make the difference between a successful product launch and costly setbacks. So, what exactly sets a leading HDI PCB manufacturer apart from the rest? Let’s break it down.

1. Advanced Technology and Manufacturing Capabilities

A top-tier HDI PCB manufacturer invests heavily in cutting-edge technology to stay ahead of industry demands. Unlike traditional PCB production, HDI boards require precision processes such as:

- Laser drilling for microvias – ensuring accurate interconnections between layers.

- Sequential lamination – supporting multiple layers without compromising performance.

- Fine line and spacing – achieving high circuit density without short circuits.

Manufacturers who adopt the latest automation, inspection tools, and computer-aided manufacturing systems are more likely to deliver consistent quality while meeting tight deadlines.

2. Strong Focus on Quality Assurance

Quality is the defining factor in PCB manufacturing. A leading HDI PCB manufacturer integrates rigorous testing and quality control measures at every stage, including:

- Electrical testing for continuity and isolation.

- Automated Optical Inspection (AOI) for detecting defects.

- X-ray inspection for hidden connections and solder joints.

Moreover, adherence to international standards such as IPC, ISO, and UL certifications demonstrates a manufacturer’s commitment to reliability. Consistency in quality ensures that the final product functions smoothly, especially in critical industries like aerospace, automotive, and healthcare.

3. Industry Expertise and Technical Support

Experience matters. Established HDI PCB manufacturers bring years of industry expertise and provide customers with valuable guidance throughout the process. This includes:

- Design for Manufacturability (DFM) support to optimize PCB layouts.

- Suggestions for cost-effective materials without compromising performance.

- Early detection of potential design flaws before production.

Leading manufacturers don’t just act as suppliers; they act as partners, working closely with clients to turn complex designs into manufacturable, high-performance boards. At Insight PCB, for instance, technical collaboration is a core part of helping customers bring their ideas to life efficiently.

4. Ability to Handle Complex Designs

HDI PCBs often involve blind and buried vias, stacked microvias, and multiple sequential laminations. Not every manufacturer can handle such complexity effectively.

A leading HDI PCB manufacturer:

- Offers flexible design capabilities to accommodate unique product requirements.

- Can produce multilayer boards with 8+ layers while maintaining signal integrity.

- Has expertise in high-frequency and high-speed applications, crucial for advanced electronics.

This level of expertise ensures that even the most challenging designs can be manufactured without delays or excessive costs.

5. Use of High-Quality Materials

The choice of materials directly impacts the performance and longevity of HDI PCBs. Top manufacturers work with reputable material suppliers and ensure that the substrates, copper foils, and laminates meet strict industry standards.

They also consider:

- Thermal performance – ensuring boards withstand heat without warping.

- Signal integrity – preventing data loss in high-speed circuits.

- Environmental compliance – using RoHS-compliant materials for sustainability.

This attention to detail guarantees reliability in demanding environments.

6. Scalability and Production Flexibility

Another aspect that sets leading manufacturers apart is their ability to scale production seamlessly. Whether it’s prototyping, low-volume runs, or mass production, a top HDI PCB manufacturer ensures:

- Quick turnaround times for prototypes.

- Cost efficiency for medium- to high-volume production.

- Consistent quality across all order sizes.

This flexibility makes them an ideal partner for startups, SMEs, and global enterprises alike.

7. Strong Commitment to Innovation

Innovation is at the heart of the PCB industry. With increasing miniaturization and complexity, manufacturers who continuously invest in research and development (R&D) stay ahead of the curve.

Leading HDI PCB manufacturers are often pioneers in adopting:

- New fabrication techniques to reduce costs and improve performance.

- Eco-friendly practices to minimize environmental impact.

- Smart factory solutions leveraging AI and IoT for efficient production.

Their forward-thinking approach ensures customers benefit from the latest advancements in PCB technology.

8. Excellent Customer Service and Communication

Even with advanced technology, strong customer support is what builds long-term partnerships. A reputable HDI PCB manufacturer offers:

- Transparent communication during the entire project lifecycle.

- Dedicated account managers for personalized support.

- After-sales assistance for troubleshooting and improvements.

This customer-first approach not only enhances trust but also ensures smoother project execution.

9. Global Reach and Supply Chain Strength

With the globalization of the electronics industry, supply chain resilience has become crucial. A leading HDI PCB manufacturer typically has:

- Multiple production facilities or global partnerships.

- Strong logistics networks to ensure timely delivery.

- Contingency plans to handle material shortages or disruptions.

Such reliability gives clients confidence that their projects won’t face unexpected delays.

Conclusion

The difference between an average HDI PCB supplier and a leading HDI PCB manufacturer lies in more than just pricing. It’s about technology, expertise, quality assurance, customer support, and innovation.

When choosing a manufacturer, businesses should carefully evaluate their capabilities, certifications, and commitment to excellence. At Insight PCB, the focus is on combining advanced technology with customer-centric service to deliver world-class HDI PCBs that meet diverse industry needs.

Partnering with the right HDI PCB manufacturer ensures not only reliable boards but also long-term success in an increasingly competitive electronics market.