In the rapidly evolving world of industrial design and DIY innovation, the “glue” that holds our world together is undergoing a silent revolution. As we move into 2026, 3M adhesives have transitioned from being simple sticky substances to high-performance engineering tools. From the smartphones in our pockets to the electric vehicles (EVs) on our roads, 3M adhesive products are increasingly replacing traditional nuts, bolts, and welds.

But why is this happening now, and how do you choose the right one for your specific needs? This guide breaks down the science of bonding, the latest trending applications, and the “how-to” of modern adhesion.

What are 3M Adhesives? Understanding the Science of Bonding

At its core, an adhesive is a material capable of holding at least two surfaces together in a strong and permanent manner. However, 3M adhesives leverage advanced “materials science” to go beyond simple sticking.

The Two Pillars of Adhesion:

-

Adhesion: This is the force that allows the adhesive to “wet out” and grip the surface of the substrate.

-

Cohesion: This is the internal strength of the adhesive itself—the ability of the glue to hold its own structure together under stress.

3M has spent decades perfecting the balance between these two forces, creating 3M adhesive products that can support the weight of a skyscraper glass panel or remain gentle enough for medical bandages on sensitive skin.

Why Choose Adhesives Over Mechanical Fasteners?

The biggest trend in 2026 manufacturing is “lightweighting” and “aesthetic integration.” Traditional fasteners like rivets and screws create stress points and ruin the sleek look of modern products.

1. Stress Distribution

Mechanical fasteners concentrate all the force on a single point (the hole). 3M Adhesives distribute the stress across the entire surface area of the bond, which significantly reduces material fatigue and prevents cracks.

2. Bonding Dissimilar Materials

In 2026, products are rarely made of just one material. We see “aluminum-to-carbon-fiber” or “plastic-to-steel” combinations everywhere. Welding these is often impossible, and drilling holes weakens them. Adhesives provide a seamless bridge between different materials without damaging their structural integrity.

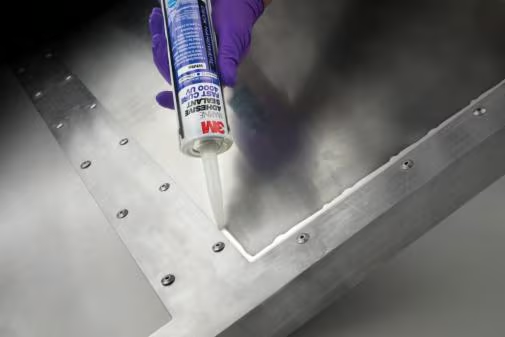

3. Corrosion Prevention

When you drill a hole for a bolt, you create a path for moisture and rust. 3M adhesives act as a sealant, preventing “galvanic corrosion” (the reaction that happens when two different metals touch) and keeping joints airtight.

Trending Now: 3M Adhesives in the 2026 EV Revolution

If there is one industry dominating the conversation around 3M adhesive products in 2026, it is the Electric Vehicle (EV) sector.

Battery Pack Assembly

EV batteries generate immense heat and are incredibly heavy. 3M has developed specialized structural adhesives that not only hold the battery cells in place but also provide:

-

Thermal Management: Helping to move heat away from sensitive cells.

-

Vibration Dampening: Protecting the battery from the constant “shake and bake” of road travel.

-

Crash Safety: Ensuring the battery remains contained even in the event of an impact.

How to Choose the Right 3M Adhesive Product

With thousands of options available, selecting the right one can feel overwhelming. To simplify the process, use this “Material Audit” checklist:

Step 1: Identify Your Substrates

-

High Surface Energy (HSE): Materials like stainless steel, copper, and glass are easy to bond.

-

Low Surface Energy (LSE): Materials like polypropylene (most plastics) and powder-coated paints are “non-stick” by nature. You will need specialized products like the 3M™ Scotch-Weld™ Structural Plastic Adhesive DP8010 Blue to grip these surfaces.

Step 2: Consider the Environment

-

Temperature: Will the bond be exposed to the summer heat inside a car (up to 180°F) or the freezing cold of an outdoor sign?

-

Chemicals: Will it come into contact with oils, cleaning agents, or fuel?

-

UV Exposure: Will sunlight break down the bond over time?

Step 3: Determine the Load Type

-

Structural Bonds: If the adhesive is holding the weight of the product, you need an epoxy or acrylic (Structural).

-

Non-Structural Bonds: For gaskets, trim, or insulation, a pressure-sensitive tape or spray adhesive is usually sufficient.

Top 3M Adhesive Categories You Should Know

| Category | Popular Product | Best For… |

| VHB™ Tapes | 3M VHB 5952 | Mounting heavy signage or panels without screws. |

| Structural Epoxies | Scotch-Weld DP420 | High-strength bonding of metals and composites. |

| Spray Adhesives | Super 77 | Lightweight bonding of fabric, foam, and cardboard. |

| Instant Bonds | 3M Scotch-Weld PR100 | Plastic and rubber “super glue” applications. |

Understanding “Bonding Intent”

In 2026, search engines are smarter. They don’t just look for keywords; they look for intent. When you are looking for 3M adhesives, you are likely looking for a solution to a specific problem.

-

If you search “How to fix a car trim,” you are looking for adhesion to plastic and weather resistance.

-

If you search “Industrial metal bonding,” you are looking for shear strength and weld replacement.

3M categorizes their products semantically to match these needs. For example, their “Fastbond” line is for speed, while “Scotch-Weld” is for structural integrity.

Pro Tips for a Perfect Bond Every Time

Even the best 3M adhesive products will fail if the surface isn’t prepared correctly.

-

Clean it: Use a 50/50 mixture of Isopropyl Alcohol (IPA) and water. Oils from your fingers are the #1 cause of bond failure.

-

Abrade it: For structural bonds, lightly scuffing the surface with a Scotch-Brite™ pad increases the surface area for the glue to grab.

-

Dwell Time: Most adhesives need time to “set.” While some reach handling strength in minutes, full chemical cure usually takes 24 hours.

Conclusion: The Future is Adhesive

The era of the “clunky bolt” is fading. As industries strive for cleaner designs, lighter products, and faster assembly lines, 3M adhesives are proving that sometimes the strongest connection is the one you can’t see.

Whether you are a professional engineer or a weekend warrior, understanding the power of 3M adhesive products allows you to design without limits.