Choosing the right air distribution manufacturing partner will be quite important in the success of your HVAC business. The quality of air distribution systems has direct consequences on energy efficiency, long-term maintenance expenses, and indoor comfort. An inappropriate decision leads to a rise in operational expenses, added maintenance, and unsatisfied occupants of a building.

Knowing What You Need for Your Project

Before you start seeking a manufacturer of air distribution, you need to ensure that you are clear regarding the needs of your project. The key to locating the best manufacturer according to your needs will depend on several factors, the most important of which is the size of the building, the occupancy rates, and the intended use thereof. Homes and office structures require a type of solution, whereas industrial structures must overcome specific challenges.

In your area, the climate is also very important. Manufacturers with knowledge about the local building codes and weather conditions will design systems that work better in your specific conditions. The businesses of several people flourish in hot and balmy weather, although some companies prefer working in cold weather.

The manufacturers you may take into consideration depend on your budget. But since it operates inefficiently and has to be serviced more often, the most economical option is often quite costly in the long-term perspective. When comparing several air distribution manufacturer, one should take into account value rather than the initial cost.

Assessing Standards and Manufacturing Quality

There is fine craft in the details. Find companies that maintain proper certification, and those that are within the industry will follow rules and standards. By demonstrating that the maker satisfies particular performance and safety standards, these certificates safeguard your investment.

There is a lot to learn about long-term durability from the materials used in building. The materials used in high-quality air distribution terminal units are resistant to corrosion, and the manufacturing tolerances are exact. Low-quality devices may appear identical at first, but under typical working circumstances, they will break considerably more quickly.

The quality of the production process is also demonstrated via testing procedures. Before being released, items from reputable air distribution manufacturers undergo comprehensive testing. In addition to marketing promises, they can offer dependability information, efficiency ratings, and performance data supported by real testing findings.

Selection of Products and Customization Choices

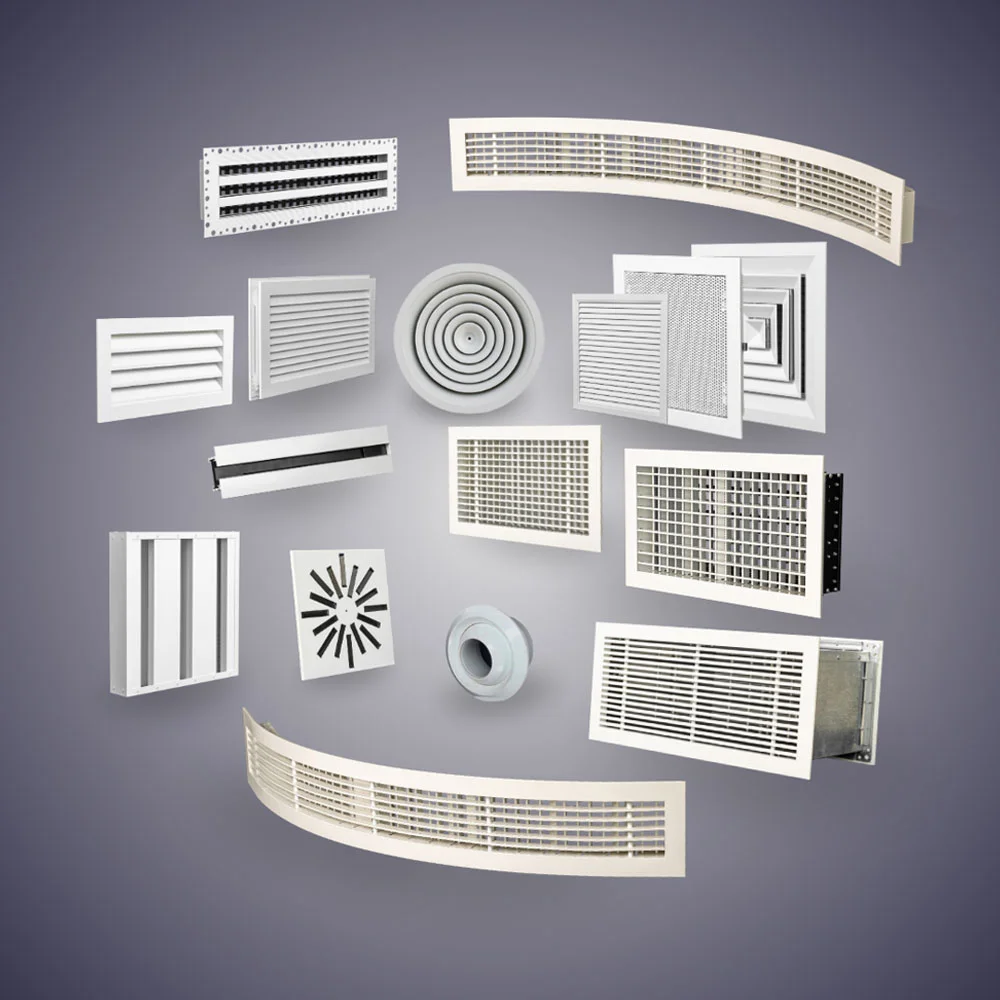

Products that meet your particular application needs are available from a reputable air distribution manufacturer. Other tasks require custom designs, and others require standard solutions. Companies that offer a more extended product line usually have more chances to take care of needs and do not need to sacrifice when it comes to satisfying everyone.

Customization capabilities become crucial when your application cannot be served by standard goods. When necessary, the top manufacturers are able to alter preexisting designs or develop entirely original solutions. This adaptability frequently separates successful projects from ones that never quite work out as planned.

Experienced manufacturers know which designs are appropriate for various purposes, and air distribution terminal units come in a variety of forms. They can direct you toward options that maximize efficiency while adhering to financial restrictions.

The services of engineering and technical support

The difference between good and mediocre manufacturers is strong technical assistance. You may save time and money by getting prompt technical support when you run into installation or performance problems. Seek out producers who offer thorough installation instructions and support for difficulties.

The value of engineering services is substantial, particularly for intricate projects. A few air distribution manufacturers have engineers on staff who can assist with integration issues, calculations, and system design. This knowledge comes in very handy when dealing with complex building designs or high-performance standards.

Training initiatives for maintenance staff and installers demonstrate the manufacturer’s concern for optimal system functioning. The lifespan and efficiency of equipment are maintained by properly installed and maintained systems by skilled personnel.

Supply Chain Lead Times and Dependability

Having dependable delivery dates helps you stay on schedule. Timelines are tight for construction projects, and entire job sites might be held up by delayed air distribution terminal units. Deliveries are regularly made by manufacturers with robust supply systems, even during peak times.

Geographical closeness influences the availability of emergency support as well as shipping costs. In comparison to suppliers that are located far away, local or regional air distribution manufacturers frequently offer quicker service and lower delivery costs. Don’t compromise quality for convenience, though.

The inventory management practices affect dependability as well. The preparedness to sudden orders or emergencies can be fulfilled by manufacturers who maintain enough stock ready in their inventory. Businesses with low inventory levels may leave you waiting during crucial project stages.

Performance Over Time and Warranty Protection

Existing installations’ performance data gives you the best idea of how well a product will work in your application. Operating system performance metrics and references from related projects can be obtained from reputable air distribution manufacturers.

Warranty conditions show how confident the manufacturer is in their goods. The fact that the company offers extensive warranties for both labor and parts shows how much it values its air distribution terminal units. Make sure to comprehend the duration of protection and the coverage provided by the guarantee.

Maintenance needs have a big impact on long-term operating expenses. No matter how much they cost to buy, systems that require expensive replacement parts or regular maintenance are more expensive to run. Seek manufacturers who offer easily accessible spare parts and acceptable maintenance requirements for their devices.

Conclusion:

You can better grasp price structures and market options by comparing several manufacturers. At least three qualified air distribution manufacturers should be asked for full offers so you may compare their offerings in terms of goods, services, and pricing.

Verified references offer important information about real performance and service caliber. Ask detailed questions concerning product performance, delivery dependability, and service responsiveness when you get in touch with recent clients. In these discussions, information is often disclosed that may not be disclosed during official presentations and may be very important.

They should not give much focus on pricing or on a specific feature, but there are many variables to consider when making a choice. During the entire life of the system, the manufacturer of the company that provides the proper air distribution delivers fair prices, service, and high-quality products that provide good value.