For decades, Chennai has been regarded as one of India’s most vibrant manufacturing and industrial centers. Home to major automakers, logistics firms, and exporting houses, the city’s need for strong, inexpensive, and effective packing supplies has grown dramatically. Packaging has evolved from merely a protective layer as companies grow their activities over domestic and world markets to become a vital part of preserving product quality, safety, and brand image.

Local producers have been urged by the consistent industrial development to create sophisticated materials guaranteeing sustainability as well as utility. Among these, bubble sheets and polypropylene (PP) sheets are becoming well-known for their adaptability in packaging, storage, and transit. Their increasing demand has spawned a fresh wave of specialized companies spurring innovation inside Chennai’s cutthroat industrial environment.

The Part of Defensive Packing in Contemporary Businesses

Strong and trustworthy packaging is essential for every business nowadays to maintain product integrity. Proper packing guarantees goods stay safe from outside damage whether they are components for heavy machinery, glassware, or electronic equipment. Chennai’s packaging sector is moving from traditional materials to high-performance alternatives that minimize trash and boost productivity.

Keeping quality during shipment increasingly depends on protective materials like bubble sheets, foam rolls, and corrugated boards. By acting as a buffer against temperature changes, vibrations, and impacts, these materials help to lower returns and increase consumer happiness. Industries now want recyclable and lightweight solutions that preserve durability without sacrificing environmental criteria as sustainability gains ground.

Bubble Sheet Makers in Chennai’s Advanced Solutions

Chennai’s Bubble Sheet Manufacturers in Chennai has transformed the regional packaging business with products made for business as well as industrial applications. These companies focus on producing multi-layered, air-filled sheets that provide outstanding cushioning and damage avoidance during transit. Known mostly for their flexibility and resilience, bubble sheets shield fragile goods including electronics, pottery, and automobile components from shock and vibration.

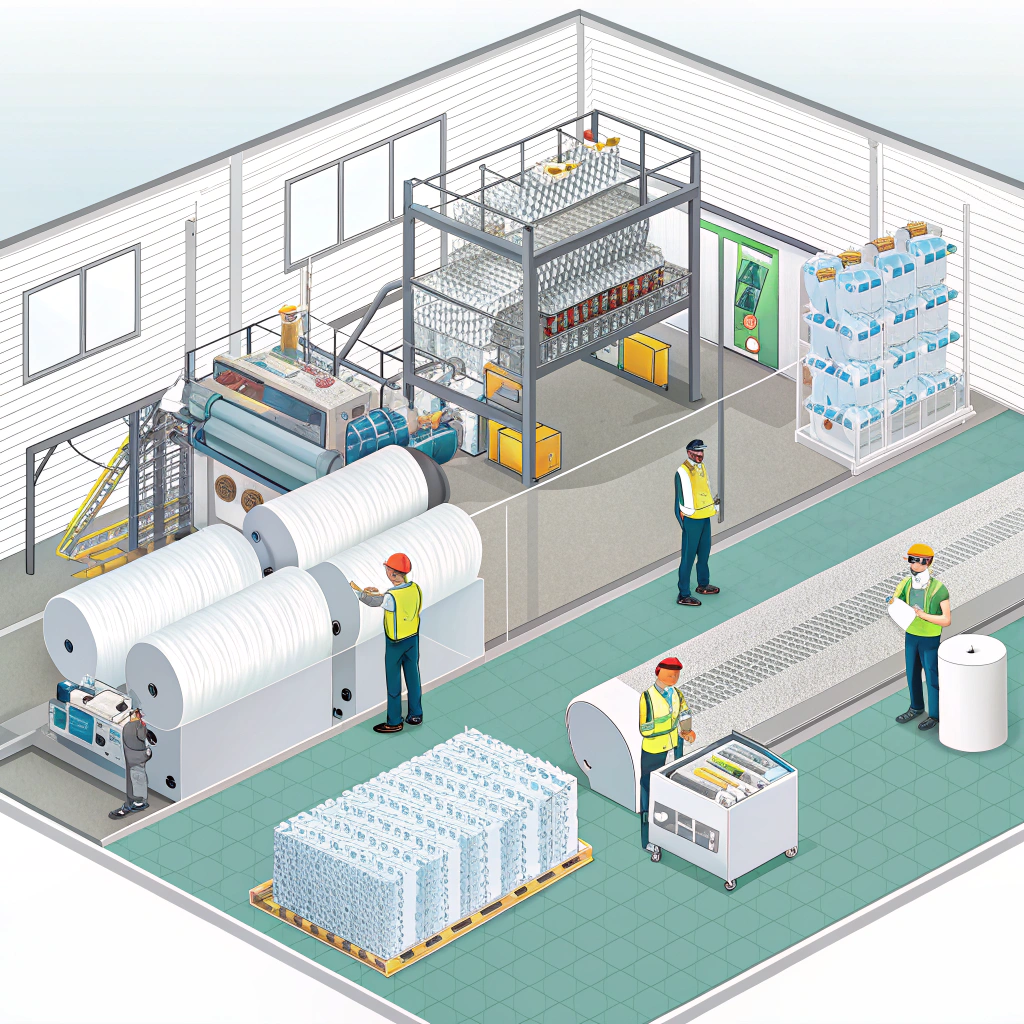

Most producers use sophisticated extrusion and sealing techniques that let them create sheets of diverse thickness, bubble sizes, and roll widths. Often including automated quality inspection systems, their facilities guarantee constant performance. Apart from the conventional transparent rolls, colored and anti-static versions are gaining prominence particularly for electronics and export sectors.

The creative bent of these companies goes beyond the quality of their products. To lessen their ecological footprint, they sometimes use recyclable materials and eco-friendly manufacturing techniques. Some even provide biodegradable bubble films, which are becoming quite popular among companies using environmentally friendly packaging methods.

Personalization has also become rather important. Companies may purchase sheets designed to meet particular needs—whether it be perforation for simple tearing or thickness for added cushioning. Supporting industries including logistics, shipping, healthcare, and e-commerce, Chennai’s producers are experts at offering affordable and efficient solutions.

Demand for bubble packaging has been somewhat increased by the expanding e-commerce environment of the city as companies look for light materials that help to reduce shipping expenses without sacrificing product integrity. To support this vibrant industry, local manufacturers have moved rapidly, growing their capacity and guaranteeing regular supply.

Advantages of Packaging with Bubble Sheets

Still among the most adaptable packing materials around today, bubble sheets provide several benefits across sectors:

• Superior defense: The air-filled construction absorbs shocks, therefore avoiding fracture or bending.

• Light weight character: Cuts shipping weight, therefore lowering logistic costs for companies.Effective barrier against humidity, guaranteeing product integrity during transit is water resistance.

• Flexibility: Fill boxes or easily wrap around oddly formed objects.

High-quality sheets can be used several times, therefore supporting sustainability initiatives.

In industries including electrical appliances, household goods, automotive parts, and export packaging, these advantages render bubble sheets absolutely essential. Chennai’s producers keep improving production processes to improve cost-effectiveness, recyclability, and durability as demand grows. Emerging Market Trends in Chennai’s Protective Packaging Industry

Chennai’s packaging industry is seeing innovation driven by the rise in worldwide commerce and e-commerce. Companies are moving from general materials to product-specific solutions that save room, minimize weight, and enhance presentation. Three main pillars guiding the course of the industry are automation, sustainability, and customisation.

Automation improves constancy while cutting production time and errors. Many Chennai businesses currently provide precision-engineered rolls and sheets using automatic cutting, lamination, and heat-sealing machines.

Packaging choices are still shaped by sustainability trends. Recyclable materials, energy-efficient manufacturing, and biodegradable plastic utilization are becoming more popular. Rising support for eco-friendly policies among customers and legislators motivates regional producers to invest in green technologies.

Customizing has made packaging into a branding asset. Companies today favor materials that express their identity via printing, color, or design, so enabling packaging to be both defensive and marketing purposes.

Properties of Polypropylene Sheets: Strength and Versatility Another major advancement in industrial packaging is polypropylene (PP) sheets. PP sheets are well-known for their chemical resistance and durability; hence, they are extensively employed in projects other than packaging such as signs, partitioning, and automotive interiors. Their adaptability and recyclability make them a popular replacement for conventional materials like wood or metal.

PP sheets offer structural integrity in industrial applications, resist moisture and impact while still keeping a light profile. Their slick surface makes customizing and cleaning simple. Adaptable for storage and transport requirements, they come in several colors, sizes, and thicknesses.

Unlike substances prone to breaking or corrosion, polypropylene resists severe conditions. This makes it perfect for extended usage, especially in logistics applications where strength and constancy are vital. Along with their industrial adaptability, PP sheets are frequently welded, cut, or shaped into various forms to produce boxes, dividers, and trays.

Chennai PP Sheet Manufacturer: Reliability and Innovation

Because of the perfection of every PP Sheet Manufacturer in Chennai, the packaging and materials business has experienced amazing expansion. In producing polypropylene sheets meant for a broad variety of uses, these companies give creativity, quality, and sustainability top emphasis. Their inexpensive, lightweight goods satisfy demands throughout several commercial sectors since they are strong against physical and chemical stress.

Many Chennai-based companies run cutting-edge extrusion and calibration systems at modern manufacturing sites. These systems guarantee consistent texture, exact measurements, and uniform thickness throughout every piece generated. Before being delivered to consumers, products undergo rigorous quality control to ensure long-lasting performance and dependability.

Their activities center on environmental accountability. Several Chennai companies have started recycling programs on their premises to turn plastic waste into useful raw resources. These environmentally aware activities help customers to meet their sustainable operational objectives as well as help to reduce garbage.

Driven by Chennai’s great industrial base and logistical infrastructure, the PP sheet market there is growing quickly. These sheets are provided by manufacturers to industries including construction, agriculture, packaging, advertising, and automobiles. For industrial customers, polypropylene is still a preferred material due of its affordable, strength, and adaptability qualities.

Contribution of Packing Innovation to the Economy of Chennai

Chennai’s economic development has been greatly aided by the development of packaging materials. Many medium and small-sized companies depending on excellent packaging call the manufacturing clusters of the city—spread across Ambattur, Sriperumbudur, and Guindy—home. New job and export possibilities are being opened up by manufacturers as they keep creating.

Local production guarantees less reliance on imported supplies, therefore lowering business costs and strengthening regional supply chains. Chennai’s advantageous placement as a port city also facilitates simple exporting of these goods throughout South and Southeast Asia, therefore growing the reach of local producers and positioning them as worldwide suppliers.

Chennai’s businesses have also been able to match international standards thanks to the focus on sustainable packaging, therefore opening opportunities for collaborations with environmentally aware global companies. As a progressive manufacturing center, Chennai’s identity is continuously strengthened by the technology, quality, and sustainability inclusion of the packaging industry.

Sustained Methods Guiding Chennai’s Packaging’s Future

Last remarks: Chennai’s direction in cutting-edge packaging solutions

Chennai is leading in industrial packaging invention fueled by a strong manufacturing ecosystem, technology adoption, and sustainable expansion. Whether it be sophisticated cushioning materials from bubble sheet makers or long-lasting polymer solutions provided by polypropylene sheet producers, the industry in the city keeps standards for dependability and quality.

Business cooperation with packaging experts guarantees ongoing innovation, increased efficiency, and environmental awareness. Chennai’s producers are ideally positioned to address new problems as international markets develop using advanced materials that strike a balance between performance, safety, and environmental friendliness.

Chennai’s contribution to the field shows the city’s ongoing dedication to advancement and industrial perfection in a time when packaging shapes brand reputation and operational efficiency.

Nowadays, Chennai’s packaging business sees sustainability as a major engine of invention. Manufacturers are aggressively creating environmentally friendly alternatives that provide the same performance standards as conventional materials yet greatly lower environmental effect.

Manufacturers are coordinating their activities with the city’s larger green policies by highlighting recycling, less material waste, and energy-efficient manufacturing. Minimizing resource use, several companies have installed solar-powered production systems and water recycling facilities.

This change is further speeded by consumer awareness and corporate responsibility. Organizations trying to improve their brand image are more and more selecting vendors that adhere to ethical manufacturing methods. Chennai’s bubble sheet and PP sheet makers are responding admirably, therefore turning sustainable packaging into not only a need but also a competitive edge.