Introduction

Gutters are an essential component of any building, guiding rainwater away from the foundation, preventing erosion, and protecting walls and landscaping. Properly installed gutters ensure a building’s longevity and reduce costly repairs caused by water damage. However, installing gutters manually can be labor-intensive, time-consuming, and prone to errors. This is where gutter machines become indispensable.

What Are Gutter Machines?

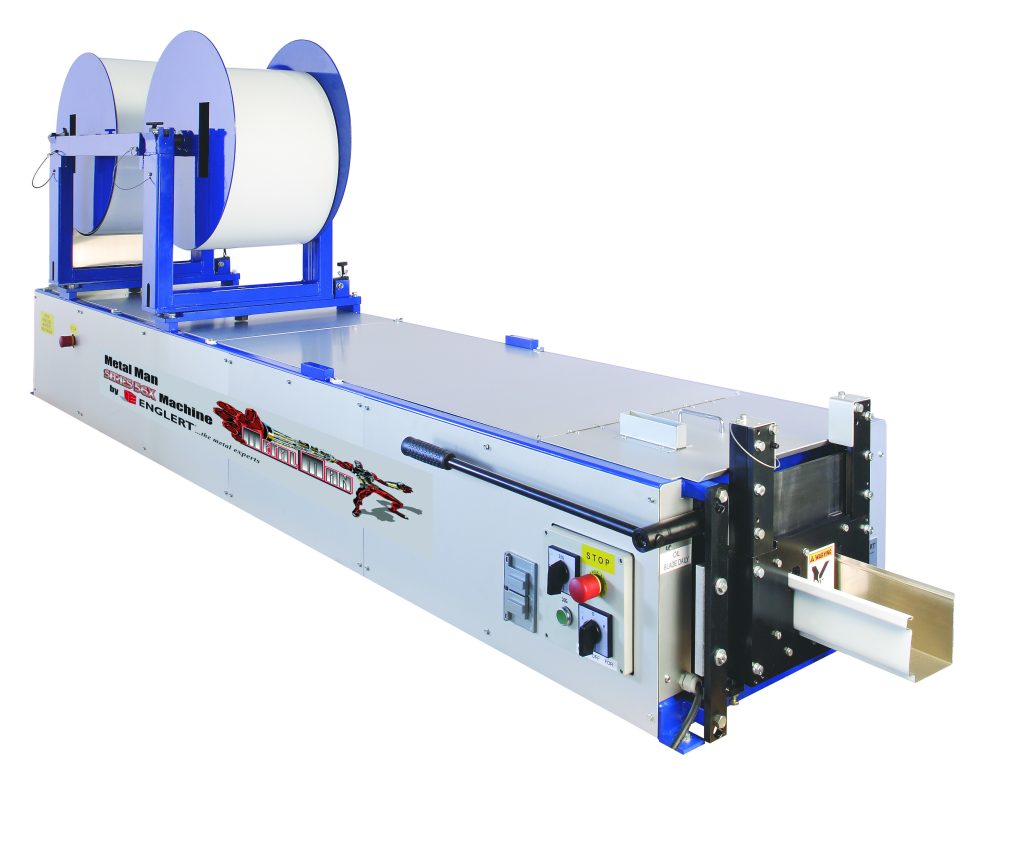

Gutter machines are mechanical or automated systems that fabricate gutters directly from metal coils, typically aluminum or steel. These machines roll, shape, and cut the material into custom gutter lengths, often producing seamless gutters that reduce the risk of leaks and increase structural integrity.

By using gutter machines, contractors can streamline the installation process, minimize material waste, and improve accuracy. These machines vary in size and complexity, from portable, job-site models to larger industrial machines capable of producing gutters for large commercial projects.

Types of Gutter Machines

Seamless Gutter Machines

Seamless gutter machines create continuous lengths of gutters without joints, which reduces leaks and maintenance. They are widely used for residential and commercial applications, producing high-quality gutters on-site.

Benefits:

- Reduced leaks due to fewer seams

- Custom lengths for a perfect fit

- Faster installation compared to sectional gutters

Portable Gutter Machines

Portable models are compact and lightweight, designed for contractors who frequently move between job sites. They are capable of forming gutters on-site, allowing for precise installation without the need for transportation of pre-made sections.

Benefits:

- Easy to transport

- Customizable gutter lengths

- Ideal for residential projects

Industrial Gutter Machines

Industrial gutter machines are large-scale systems designed for producing gutters in bulk. They are commonly used by manufacturers and large contractors handling multiple projects simultaneously. These machines can handle thicker materials and higher production volumes.

Benefits:

- High production capacity

- Handles thicker and wider materials

- Suitable for commercial and industrial projects

Accessories and Add-Ons

Many gutter machines come with additional features, such as downspout crimpers, cutters, and rollers for adding decorative patterns. These accessories enhance the versatility of the machine and allow contractors to offer customized gutter solutions.

Advantages of Using Gutter Machines

Precision and Accuracy

Gutter machines produce consistent, precise gutters that fit perfectly along a building’s edge. Unlike manual installation, which can result in uneven lengths and gaps, machine-produced gutters align accurately, ensuring proper water flow and minimizing leaks.

Time Efficiency

Installing gutters manually can take days, especially for large buildings. Gutter machines significantly reduce installation time by producing continuous gutter lengths on-site. Contractors can complete projects faster, increasing productivity and customer satisfaction.

Reduced Material Waste

Traditional gutter installation often involves cutting pre-made sections, which can lead to wasted material. Gutter machines form gutters to exact lengths, reducing offcuts and ensuring efficient use of metal coils.

Durability and Longevity

Seamless gutters produced by machines are stronger and more resistant to leaks and water damage. By eliminating joints and producing smooth, uniform gutters, these machines enhance the durability of the gutter system.

Cost-Effectiveness

While the initial investment in a gutter machine may be significant, it pays off in the long run. Reduced labor costs, minimized material waste, and faster project completion make gutter machines a cost-effective solution for contractors.

Versatility

Modern gutter machines can handle various materials and gutter profiles. Contractors can produce half-round or K-style gutters, choose different widths, and even incorporate decorative designs, allowing for greater customization and aesthetic appeal.

Applications of Gutter Machines

Residential Construction

Gutter machines are widely used in residential projects to produce seamless gutters for houses. Homeowners benefit from improved water management, reduced maintenance, and visually appealing installations.

Commercial Buildings

Commercial structures such as office buildings, schools, and retail centers often require high-capacity gutter systems. Industrial gutter machines allow contractors to produce durable gutters for large-scale projects efficiently.

Renovation and Replacement Projects

Replacing old, damaged gutters is common in renovation projects. Gutter machines allow contractors to create custom gutters that fit existing structures perfectly, reducing the need for adjustments and ensuring a seamless appearance.

Agricultural Buildings

Farms, barns, and storage facilities can also benefit from machine-made gutters. These gutters protect foundations and equipment from water damage and can be produced quickly and efficiently on-site.

Key Considerations When Choosing a Gutter Machine

Material Compatibility

Different machines are designed to work with specific metals such as aluminum, steel, or copper. Ensure the machine you choose can handle the materials you plan to use.

Portability

If you frequently move between job sites, a portable machine may be ideal. For large-scale production, industrial machines are more suitable.

Production Capacity

Consider the volume of gutters you need to produce. High-capacity machines are better for commercial projects, while smaller machines work well for residential installations.

Ease of Operation

Some machines require specialized training, while others are user-friendly. Choose a machine that matches your team’s skill level to ensure efficient operation and safety.

Maintenance and Support

Regular maintenance is essential for smooth operation and longevity. Check for available service, spare parts, and warranty options before purchasing a machine.

Conclusion

Gutter machines have transformed the gutter installation industry by providing efficient, precise, and durable solutions. Whether for residential, commercial, or industrial projects, these machines offer numerous benefits, including faster installation, reduced material waste, and enhanced gutter longevity.