In the world of automotive and engine manufacturing, precision defines performance. Whether it’s an engine piston, gearbox housing, or valve component, each part must meet strict specifications to function flawlessly. This is where understanding designer CNC tolerance tips becomes crucial. For designers, mastering CNC part tolerances is key to achieving consistent quality, ensuring interchangeability, and enhancing production efficiency across the automotive industry.

1. The Role of CNC Tolerances in Automotive Design

CNC machining has become the backbone of the automotive and vehicle parts industry due to its ability to produce high-precision components. Tolerances define the allowable deviation from the nominal dimension, ensuring that parts fit and perform as intended. In car and engine production, even the smallest error can affect performance, safety, and fuel efficiency.

For example, an engine’s piston-cylinder clearance determines how smoothly the engine operates under pressure. Tight tolerances ensure minimal vibration, heat loss, and wear — all essential for reliable engine performance. Thus, for automotive designers, tolerance control is not an afterthought but a core design principle.

2. Why Designers Must Understand CNC Capabilities

A common mistake designers make is specifying tolerances that exceed machining capabilities. While CNC machines offer impressive accuracy, tighter tolerances often mean higher costs, longer machining times, and more frequent quality checks.

Understanding the machine’s realistic precision range helps designers balance performance with manufacturability. For instance:

-

±0.001 mm to ±0.005 mm is common for moving engine components like shafts and bearings.

-

±0.01 mm to ±0.05 mm works well for static structures such as housings and mounts.

Designers who collaborate with CNC engineers during the design phase can ensure their tolerance specifications are achievable and cost-effective.

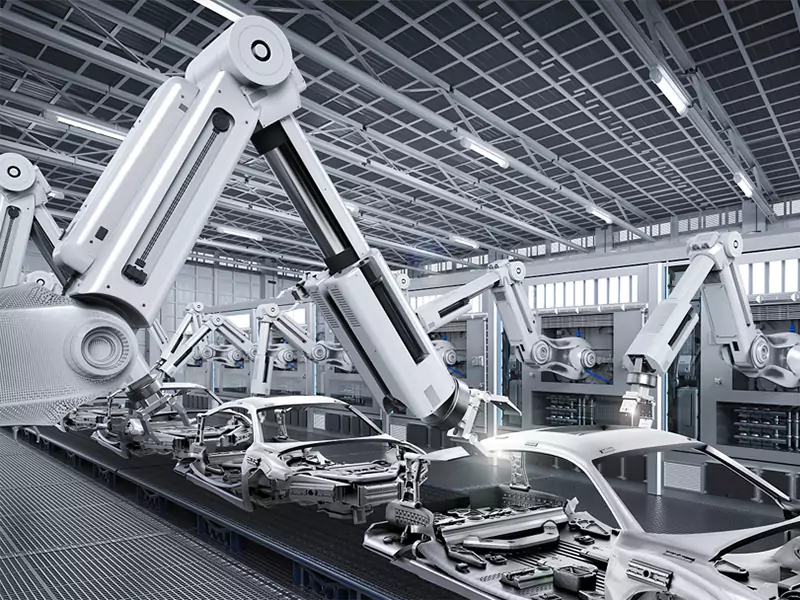

3. CNC Machining and Vehicle Engine Manufacturing

Modern cars and vehicles rely heavily on CNC machining for producing both metal and composite parts. From the engine block and camshaft to transmission gears, CNC machines create complex geometries with exceptional repeatability.

Automotive engines, in particular, benefit from tight-tolerance CNC machining because:

-

It ensures uniform heat distribution in combustion chambers.

-

It enhances mechanical efficiency by reducing friction.

-

It extends engine life by minimizing part wear.

When designers apply optimized tolerance values, they help machinists maintain accuracy across production runs — ensuring every engine performs the same way, every time.

4. Balancing Tolerance Precision and Production Costs

Precision comes at a price. Extremely tight tolerances require more precise tooling, slower feed rates, and more quality checks — all of which increase costs. Therefore, successful designers know how to prioritize tolerance precision based on part functionality.

To manage production efficiency:

-

Apply tight tolerances only where essential, such as rotating or sealing components.

-

Use standard tolerances for non-critical areas to reduce machining time.

-

Adopt Geometric Dimensioning and Tolerancing (GD&T) to control form, orientation, and location without over-restricting machinists.

This balance between design quality and production efficiency is vital for keeping automotive manufacturing both profitable and precise.

5. Real-World Example: CNC Tolerances in Engine Components

Consider an automotive crankshaft a component that converts linear piston motion into rotational energy. Every surface, groove, and bore must align perfectly to avoid vibration and maintain balance. Achieving this requires sub-micron precision during CNC machining.

Likewise, valve seats, connecting rods, and fuel injectors all rely on tight-tolerance CNC processes. By defining realistic yet accurate tolerance limits, designers ensure consistent assembly, performance, and longevity across every engine.

6. Partnering with CNC Experts for Automotive Success

Working with an experienced CNC machining company such as Yicen Precision can make all the difference. Their advanced machinery and engineering expertise help designers optimize tolerance requirements for both prototype and large-scale production.

Yicen Precision’s experience in automotive and engine part manufacturing allows clients to achieve exceptional surface finishes, exact dimensions, and superior product quality all while maintaining efficient production cycles.

By integrating these designer CNC tolerance tips, automotive designers and engineers can elevate their products’ quality, reduce costs, and strengthen their brand’s reputation for reliability.

Conclusion

Precision is the foundation of modern automotive engineering. When designers understand and apply the right CNC tolerances, they bridge the gap between creativity and manufacturability. From car engines to structural components, proper tolerance planning ensures every part fits perfectly, performs efficiently, and lasts longer on the road.

Incorporating these designer CNC tolerance tips into your workflow not only enhances part quality but also accelerates innovation in the automotive industry driving the future of smarter, more reliable vehicles.