In today’s highly competitive manufacturing landscape, precision and efficiency are non-negotiable. Whether producing automotive components, aerospace fittings, or custom mechanical parts, companies need machining partners who can deliver consistent quality and reliability. Among the most effective manufacturing methods for cylindrical and rotational parts is CNC turning a process that blends computer accuracy with expert craftsmanship.

Zintilon, a global leader in precision machining, offers advanced CNC turning services that help clients achieve superior part performance, tight tolerances, and faster turnaround times. Through innovation, digital manufacturing, and quality assurance, Zintilon empowers engineers, product designers, and manufacturers to turn ideas into high-quality components with confidence.

What Is CNC Turning?

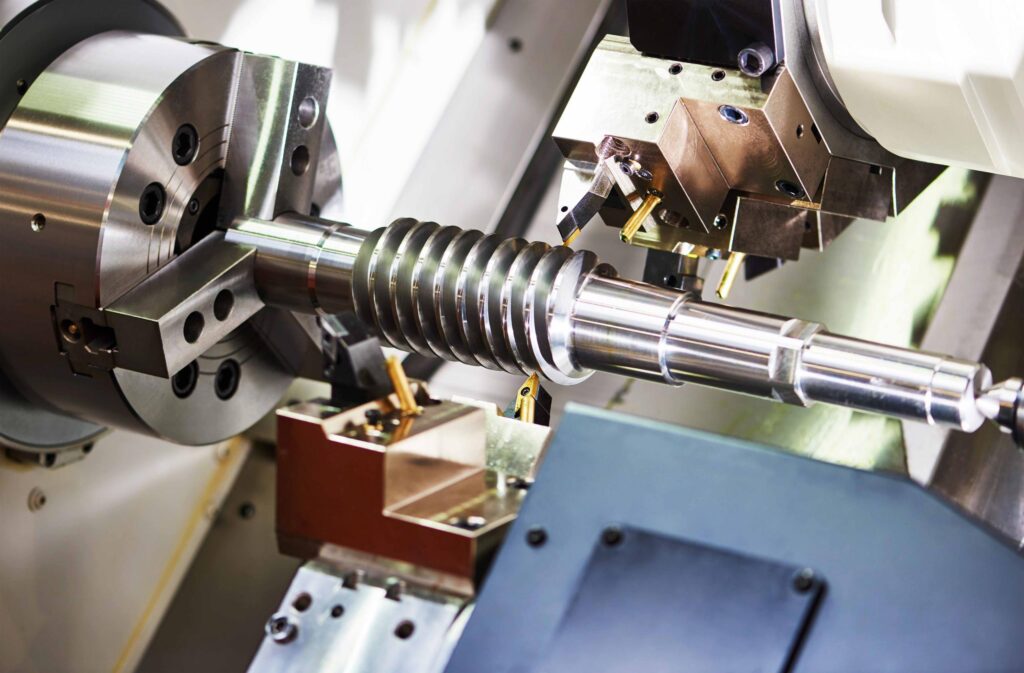

CNC turning is a subtractive machining process where a rotating workpiece is shaped using single-point cutting tools. Unlike CNC milling, which uses rotating tools and stationary material, turning involves rotating the material itself while a stationary tool removes material to achieve the desired shape.

This process is ideal for creating cylindrical or symmetrical parts such as shafts, pins, bushings, connectors, and threaded components. CNC lathes the machines used in turning — can achieve exceptional precision and surface finish, making them indispensable for critical applications across multiple industries.

Why Zintilon Leads in CNC Turning

Zintilon has established itself as one of the most trusted names in the CNC machining industry by combining advanced technology, experienced engineers, and customer-focused service. Their CNC turning capabilities are built around three key pillars: precision, efficiency, and scalability.

-

Advanced Machinery and Multi-Axis Capabilities

Zintilon’s CNC turning centers feature multi-axis configurations that enable complex part geometries, grooving, threading, drilling, and boring — all within a single setup. This not only reduces machining time but also improves dimensional accuracy and repeatability. -

Exceptional Tolerances and Surface Finishes

With tolerances as tight as ±0.005 mm and a range of surface finishing options (anodizing, polishing, coating, and plating), Zintilon ensures every part meets exact design and functional requirements. -

Wide Material Selection

Zintilon works with over 100 materials, including aluminum, stainless steel, brass, copper, titanium, and engineering plastics. Each material is precisely machined according to its mechanical properties to guarantee durability and performance. -

Scalable Production

From one-off prototypes to low-volume production runs, Zintilon’s CNC turning process is designed for flexibility. Their rapid prototyping capability allows clients to test and validate designs quickly before scaling up for mass production. -

Rigorous Quality Control

Every component undergoes a strict inspection process using advanced metrology tools. Dimensional accuracy, surface quality, and structural integrity are verified at multiple stages of production.

Industries That Depend on CNC Turning

CNC turning is essential across a variety of sectors that require precision and reliability:

-

Aerospace: Precision shafts, housings, and threaded parts for critical flight systems.

-

Automotive: Custom fittings, engine components, and drivetrain parts.

-

Medical Devices: Surgical tools, orthopedic implants, and diagnostic housings.

-

Electronics: Connectors, fasteners, and enclosure components.

-

Industrial Equipment: Rollers, pins, and coupling mechanisms.

Each industry benefits from Zintilon’s ability to produce parts that perform flawlessly under demanding conditions.

Benefits of Ordering CNC Turning Online

In an era of digital transformation, ordering cnc turning online through Zintilon’s platform offers unmatched convenience. Customers can upload their 3D CAD models, receive instant quotes, and manage their projects seamlessly from prototype to final production.

This online system streamlines communication, shortens lead times, and ensures transparency throughout the entire manufacturing process. Engineers can monitor progress, review materials, and request revisions without delays — making product development faster and more efficient.

Why Partner with Zintilon

Zintilon isn’t just a machining supplier — it’s a complete manufacturing partner. The company’s experienced engineers collaborate with clients to optimize designs for manufacturability, helping reduce costs and eliminate production challenges early on.

Key advantages of partnering with Zintilon include:

-

End-to-end project support, from design analysis to final inspection.

-

Fast global shipping and competitive pricing.

-

ISO-standard quality assurance and traceability.

-

Sustainable and waste-optimized manufacturing processes.

By integrating cutting-edge CNC technology with expert engineering insight, Zintilon ensures every project exceeds expectations in both precision and performance.

From Prototype to Production: A Seamless Process

Zintilon’s CNC turning workflow is designed to support all stages of product development. Whether you need a single prototype for testing or a batch of production-ready parts, the process remains consistent — precise, efficient, and transparent.

Their digital manufacturing platform also enables rapid scaling. Once your prototype is validated, Zintilon can transition to full-scale production without retooling or process changes, maintaining the same quality standards throughout.

Final Thoughts

In the world of precision engineering, choosing the right manufacturing partner makes all the difference. Zintilon’s CNC turning services combine innovation, accuracy, and reliability ensuring that every part meets the highest industrial standards.

With advanced technology, skilled engineers, and a commitment to quality, Zintilon continues to be the go-to choice for businesses seeking world-class turning solutions.

If you’re ready to streamline your production and achieve unmatched precision, explore Zintilon’s CNC turning capabilities today. Experience the perfect blend of technology, expertise, and performance where every detail matters.